Understand where and why flow control valves are used. The different types available and how they work.

Self-study lesson plans and training record download page.

1-2 What flow control valves do and where they are used

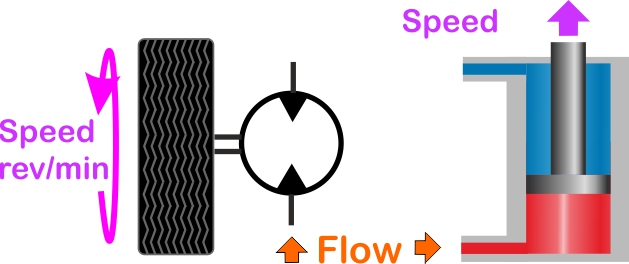

Hydraulic flow control valves are used to control the speed at which actuators move, once directional valves have opened to set the direction. Most hydraulic machines will contain several actuators, all of which will need to move at different speeds. Flow control valves are used to control the speed of movement and allow changes to be made during setup and/or operation.

Flow control valves may also be called a needle valve, throttle valve, flow regulator, orifice, restrictor valve, or priority valve. By creating a restriction in the circuit the flow rate is controlled and therefore the speed or acceleration of the load.

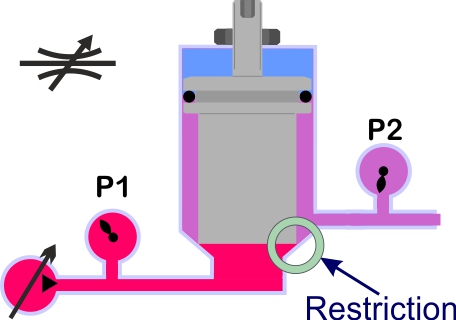

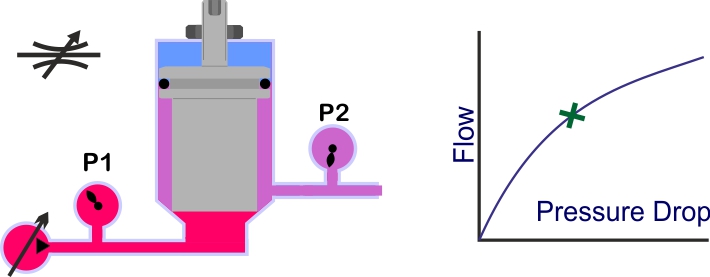

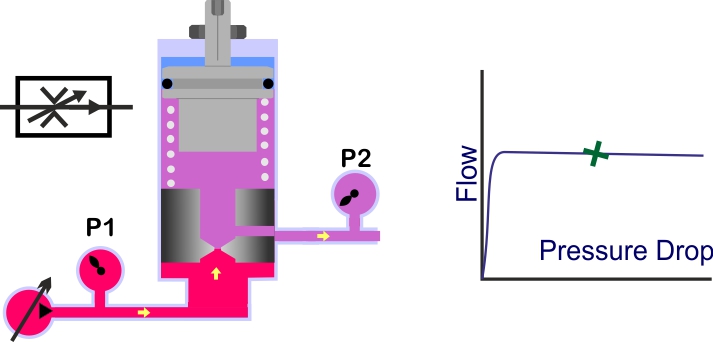

The flow across an orifice restrictor will change as the pressure drop across it changes. A pressure compensated flow control valve will give a constant flow/speed of the equipment even when the load pressure changes. In a simple throttle valve the flow is based on the pressure drop across it, so as the load or supply pressure changes, the pressure drop across it, and therefore the flow also changes.

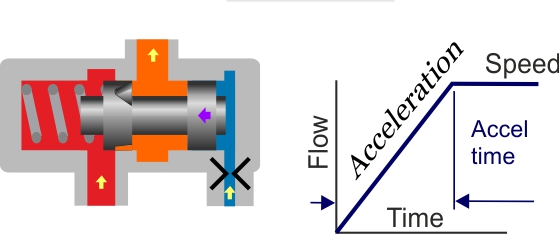

By controlling the speed that fluid flows through pilot lines e.g. restricting how quickly fluid leaves the cavity at the end of the spool, the speed at which the spool moves can be controlled. Using this method to slowly open a valve is used to provide smooth load acceleration and deceleration of an actuator and hence avoid shock loading or judder.

By controlling the speed that fluid flows through pilot lines e.g. restricting how quickly fluid leaves the cavity at the end of the spool, the speed at which the spool moves can be controlled. Using this method to slowly open a valve is used to provide smooth load acceleration and deceleration of an actuator and hence avoid shock loading or judder.

Flow control orifices are often used inside other valves to enhance their operation. Probably the most common of these is in parallel with a simple check valve to produce a valve that only restricts the flow in one direction.

Priority flow control valves are used to supply flow into one line as a priority, but only when that flow demand has been satisfied will the remainder of the flow pass into a second supply line.

Flow dividers are used to split or join flow into two equal flow rates. This can be useful for driving two cylinders at the same speed for example.

1-2 How flow control valves work

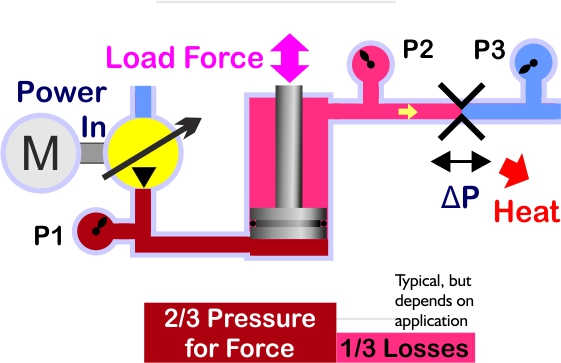

Hydraulic control is essentially a braking technology. In the same way, a car brake controls deceleration and is much smaller than the engine. A fluid brake should control the load by restricting or stopping its movement. It is typically just and small hole so is much smaller than the pump that supplies the fluid.

Variable orifice flow control

In its simplest form, a flow control valve is just an orifice. Fluid flow will increase until the p.d. (pressure drop) across the orifice is the same as the supply pressure, minus the load pressure. The supply pressure into the system must equal load pressure out of the system plus the pressure drop lost across the orifice. The pressure drop across the valve is used as a brake to control the actuator speed.

Adjustable flow control valve

Adjustable flow control valves contain an adjustable orifice. Higher quality valves have sharp edge orifice designs that provide more consistent flow across the working temperature range.

Pressure compensated flow control

Pressure compensated flow control valves contain a variable orifice whose size changes as the pressure drop across it changes e.g. a spool element moving up and down to adjust the size of the flow orifice port. This means the flow through the valves stays constant under most operating conditions and the orifice size varies instead.

Keeping loads under control

It's quite common to use high-pressure drops to ensure loads stay in control. Using 30% of the supply pressure to control the load is not uncommon.

Beware pressure intensification

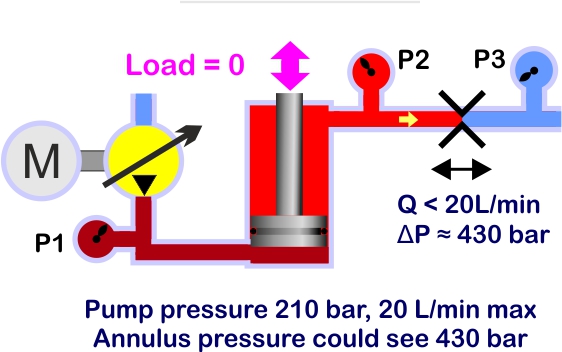

Restricting the flow from the cylinder annulus will cause a higher outlet pressure than the inlet pressure.

2-3 Different types of flow control valve

The main types of flow control valve are:

- A fixed orifice.

- An adjustable orifice needle valve.

- A fixed or adjustable orifice with a by-pass check to control the flow in one direction only.

- A pressure compensated flow control valve with or without a by-pass check.

- Flow dividers and combiners

- Priority flow control valves.

Hydraulic engineers often use the term, meter-in or meter-out flow control. In both cases, the valves are likely to be the same and it's just the way they are used that is different. With meter-in flow control we throttle the flow before the actuator. With meter-out flow control we throttle the flow after the actuator e.g. the check valve is installed the other way around.

See also the flow control valves in our symbols sections.

In mobile equipment, smooth control of actuator speed is generally very important so it is common to use proportional control valves rather than more simple, flow control valves. Cost is also very important so a simple orifice or crude adjustable orifice may be used when proportional control is not required.

In mobile equipment, smooth control of actuator speed is generally very important so it is common to use proportional control valves rather than more simple, flow control valves. Cost is also very important so a simple orifice or crude adjustable orifice may be used when proportional control is not required.

A common format for flow control in industrial applications is the double-flow control and bypass check slice, these sit below a CETOP valve. When flow control speeds are more critical, then higher quality valves exist with more accurate pressure and temperature compensation.

A common format for flow control in industrial applications is the double-flow control and bypass check slice, these sit below a CETOP valve. When flow control speeds are more critical, then higher quality valves exist with more accurate pressure and temperature compensation.

Advanced flow control valve training

Learn more about flow control valves in our 'Professional Training Section'. Understand their design features, performance limits, and how to specify flow valves.