Self-study lesson plans and training record download page.

What hydraulic pipework and fittings do and where used

Specialist hydraulic pipework and fittings are required to connect the pumps, valves, and actuators. While at first glance, this may appear quite simple, in reality, there are several difficult challenges to overcome.

Hydraulic pipework and fittings must:

Be strong enough to prevent pipework or fittings from failing, as they can become a deadly missile when they do.

Prevent leakage of the high-pressure hydraulic fluid from the system.

Ensure the optimum fluid flow rates are maintained.

Compensate for component misalignments and movement during operation.

Hydraulic pipework and fittings will be required in every hydraulic system. However, different types of fitting are used in each market sector due to a combination of historical, cost, and performance factors.

Inappropriately specified, badly designed, or poorly assembled fittings can be very dangerous; increasing the likelihood of failure, fluid leakage, or in the worst case personal injury.

Important background and history

In a study during the 1970s, the British Steel Industry calculated that hydraulic fluid leakage was costing the industry around 1 Million pounds per year. This was not just the cost of the fluid but included the cost of additional maintenance and cleaning required as a consequence of the leakage. The study also looked at potential solutions and while not everyone has applied their findings, for those who have the issue has been significant, if not totally resolved.

It is also important to understand a little of the history of hydraulic pipe fittings to better understand which types are most appropriate today. In the past, there has often been a level of acceptance that a certain amount of fluid will leak from the fittings over time. Maintenance procedures often included checking and tightening fittings when they leak. These days fluid leakage is generally not considered acceptable under any conditions and therefore a higher level of manufacturing integrity is required.

Safety requirements are also more stringent. It's not that companies care more about their employees but it's now a legal requirement for listed companies to report all workplace injuries. In recording every accident at work in great detail the major hydraulic equipment manufacturers have become aware of exactly where the injuries are occurring. Even though it may be a tiny percentage some have realised that across their entire international operations in the region of 1 to 4 people were being killed every year by failures in poorly fitted hoses and compression fittings. No matter how small a percentage this is, every death instantly becomes a board-level discussion and requires instant actions including improved training and awareness along with an insistence on using the latest and highest quality components.

While smaller companies may think they have been using certain technologies without incident for many years, they should appreciate the wider industry data and make sure they are using the latest and best techniques wherever possible.

How hydraulic pipework and fittings work

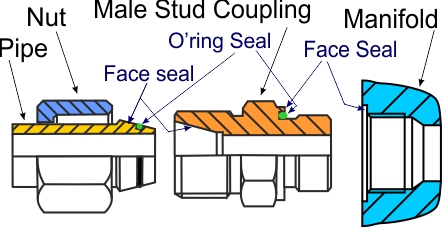

This image shows a typical hydraulic pipe and fitting arrangement. The manifold has a machined, threaded port to the male stud coupling port adaptor. The adaptor has a flat face that is clamped against the manifold and will ensure the seal is retained correctly e.g. it won't extrude out of the gap. The flat faces will probably not be machined well enough to make a seal without the Oring. The pipe connection has a 24-degree cone that will accept and align the formed pipe would also seal without an Oring, provided the pipework is not made from stainless steel. It may not be necessary to have both a metal to metal face seal and ORing seal although this will provide the best chance for maintaining a leak-free joint. The fitting performance will also depend on the nature of the hydraulic system e.g. the environment, temperatures, vibration, and severity of the pressure ripple. If the conditions under which the pipework is operating are arduous, then the most effective type of fitting will be required. If the duty is only light then lower specification fittings may be sufficient.

Rigid pipework is always used in preference to flexible hose on hydraulic systems. This is because rigid metal pipework is more durable, longer-lasting and lower cost than a flexible hose. However, because hydraulic actuators move and drive systems vibrate, we often need to use a flexible hose to allow for large deflections or isolate the hydraulic components from any additional stress or shocks.

When considering the installation of any hydraulic system the designers must consider the level of vibration or relative movement between components. They must also consider the manufacturing tolerances and flexibility of the interconnecting pipework to make sure the assemblies can be manufactured and that there is enough flexibility to avoid fatigue failures later in the equipment's life.

Different types of hydraulic pipework and fittings

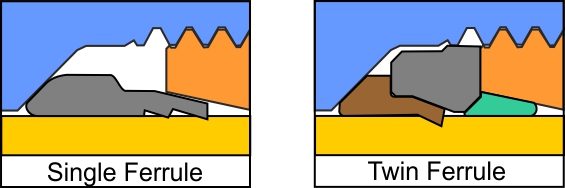

When considering the correct type of pipework and fitting for each project, the first option is likely to be simply using the same type that has been used before. There should be good logic in this as through life experience under identical conditions is generally the best way to make sure nothing unusual will go wrong. However, fitting designs continue to evolve to meet the latest safety and performance standards, so users should also consider upgrading to meet these increased demands. The image shows how a single ferrule fitting is often replaced by a twin ferrule design that includes an elastomeric seal for greater sealing efficiency.

We discuss fitting design types in greater detail in the pro-section of this site although below are a range of the currently available fitting standards.

One key development to note is the use of cold-formed pipework fittings which replaces weld nipples and cutting rings. This provides a very effective technical and low-cost solution that has provided excellent results for many years now. Pre-bent pipework can also be an effective approach with designs generally being available from 3D draughting packages.

Pre-formed thermoplastic pipework is also proving very popular. Manufacturers quote unlimited life and the ease of assembly and low weight can make it a very effective OEM (Original Equipment Manufacturer) solution.

Manifold to adaptor connection

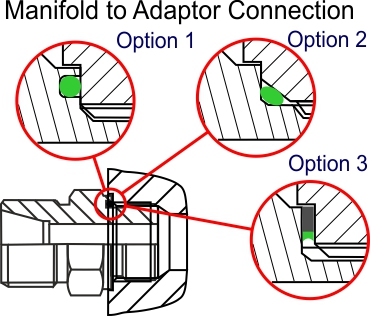

This image shows the three most common forms of sealing arrangement, although option 3 is non-preferred.

Option 1 has a retained seal, held within a groove in the port adaptor. There is still a metal to metal face seal although because this uses flat faces, it is unlikely to provide a pressure-tight fluid seal.

Option 2 has a tapered groove at the top of the manifold connection that is large enough for the o'ring seal to fit in. The manifold port form is different in both option 1 and 2 so it is important that the adaptor types are not mixed up.

Option 3 uses the same manifold port standard as option 1 except the fitting has no groove and a bonded washer is used instead of an o'ring. Bonded washers are no longer a recommended method of sealing within the hydraulics industry although they are sometimes the only option with older installations.

Fitting options that are NOT acceptable

Taper threads and Swagelok style compression fittings are not fluid power fittings. These types of fittings are sometimes used for historical reasons in the process industry or in low-pressure e applications but they are not, and never have been, acceptable fitting standards for high pressure, fluid power, hydraulic applications. Even the original Keelaring style compression ring fittings have now been superseded by more robust and reliable cutting ring designs.

The pro-section of this site contains more information on which type of modern coupling is most appropriate for each application and why.

Pipe and hose fitting options

Below are examples of some of the commonly available pipe fitting types. Use the e4training hydraulic hose register builder to identify your pipe fittings as this software includes more details of the dimensions and thread sizes etc.

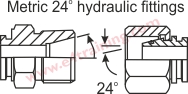

Metric 24degree cone

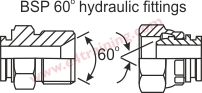

BSP 60 degree cone fitting

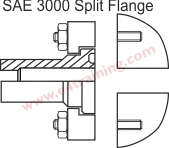

SAE 3000 and 6000 pipe fittings

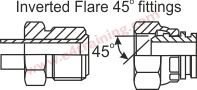

45 degree Inverted flare pipe fitting

SAE 45degree cone fitting

JIC pipe fitting

OFRS face seal fitting

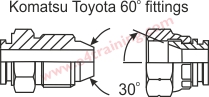

Komatsu Toyota 60degree fitting