Self-study lesson plans and training record download page.

What hydraulic cylinders do and where they are used

Hydraulic cylinders are the most common type of hydraulic actuator. They are widely used throughout almost every hydraulic machine for moving, lifting, clamping or steering, etc.

Look at every excavator working on the road works near you and you will see several large cylinders lifting and lowering each of the buckets.

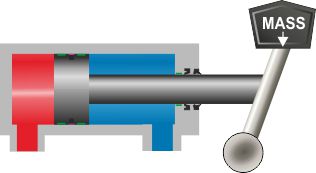

At first glance, their function looks relatively simple, e.g. pressure and flow in one side and this will move the load. However, the load itself can be very complex, pushing, pulling, smooth, or oscillating, so the cylinder area, rod length, and fluid volumes, etc are all very important factors.

How hydraulic actuators work

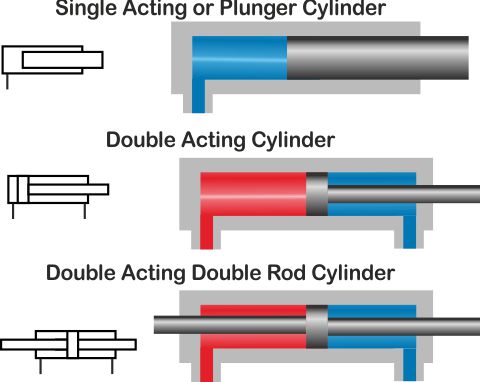

Apply pressure to the rod of a single acting or plunger cylinder, and the rod will extend unless the mechanical load on the end of the cylinder, and seal friction, are sufficient to push it back and retract the cylinder, or hold it still.

A double acting cylinder has will extend with pressure on the rod end but also retract with pressure on the annulus side. Seals prevent leakage across the piston head and rod seals stop leakage passing along the rod to atmosphere.

A double rodded cylinder is used on occasions to ensure that the annulus area is the same on both sides of the cylinder. This balances the loads and flows and ensures a more consistent control in critical applications.

Cylinder cushions

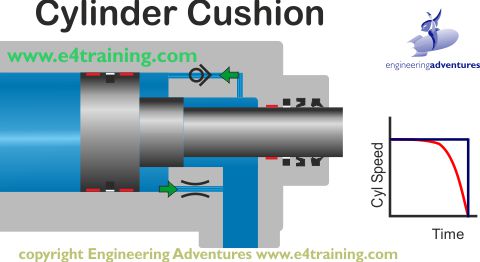

Cylinder cushions work by slowing the movement as the cylinder reaches the end of its stroke. Our diagram show how it does this by trapping fluid in a small pocket and only releasing it through a small orifice. This fluid pocket will have a check valve to stop negative pressures being generated as the cylinder annulus opens.

Different types of hydraulic cylinders

Single-acting cylinders only allow pressure on one side to extend them.

Double-acting cylinders are by far the most widely used style of cylinder. They are also available in a double rod design which has no full bore are side, but instead rods on both sides so the pressure areas remain the same. This is beneficial when loads need to be matched or when running high accuracy control systems where a finely balanced performance is required for both retracting and extending.

Telescopic cylinders are available which contain several extending sections allowing them to extend to over two or three times their retracted length.

Cylinders come in a wide range of mounting styles. Suitable mounting is critical for avoiding side loads on the cylinders as well as the risk of buckling the rods. These include Clevis, plain, self-aligning, trunnion, flange, or foot mounting.

Cylinders generally fit into one of three main groups. Welded cylinders offer the best value but the lowest pressure and shortest working life. Tie rod cylinders have better performance characteristics and are generally used in industrial rather than mobile applications. Finally, Mill Cylinders have the highest performance and durability ratings. But refer to manufacturer datasheets for actual performance ratings.

Other available options include cushions, to smooth the rod deceleration, and bleed nipples to vent out air while commissioning. There are many different seal types, each designed to work under different duties or environmental conditions. Position feedback systems can also be built directly into the cylinder to help positional control systems.

Advanced Actuator Training

- Tips for operating and maintaining

- How to specify hydraulic actuators

- Design Tips, techniques, and potential issues